So, all you need to do is browse through this list and find the best laser cutter for you.Īnd don’t worry! Because even though there are no rankings, I’ve been super honest with these reviews.

I’ve put together my notes to create this informative guide to make things a tad bit easier for you. Recently, I was doing my research on the laser engraver tool, trying to find the one perfect for me. Lucky for you, this is where I step in to help! So, if you are not sure where to start, it can be difficult to zero in on the best laser engraving machine.

With an increase in popularity, you also have plenty of options to choose from. With this amount of freedom of flexibility and customization, it comes as no surprise as to why this piece of equipment is such a hit in the market today.

Wood engraving machine free#

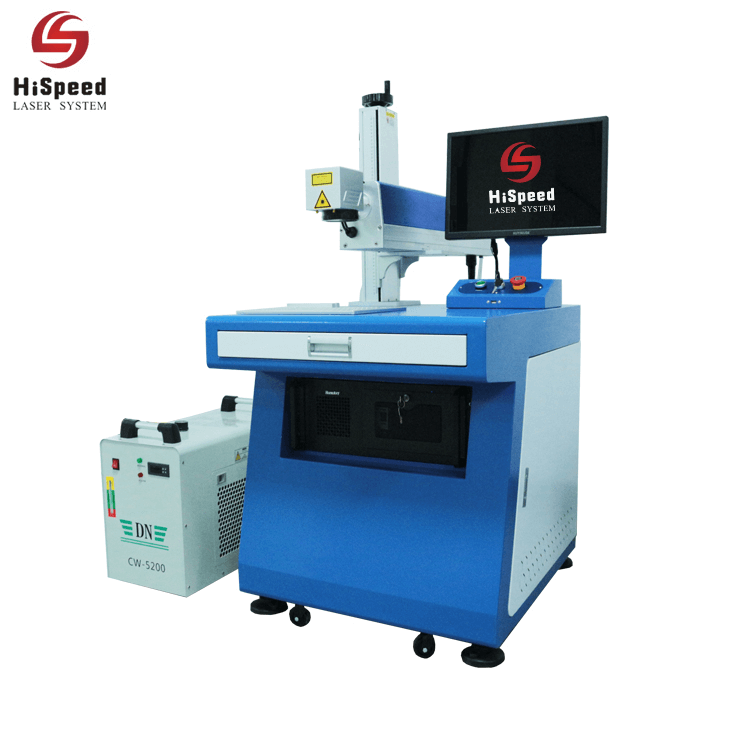

If you are interested in it, please feel free to contact us.Whether you are a DIY fanatic or someone who works in the engineering industry, you would have definitely come across this 3d laser printer that cuts your tools with excellent precision.

Only the beginning of the CNC engraving machine concept, the advantage of the engraving machine in the carving, if the processing material hardness is relatively large will also appear powerless.The emergence of the carving machine can be said to fill the gap between the two.CNC engraving and milling machine can be carved, but also milling, is a highly efficient and high precision CNC machine tools.ġ,its spindle speed is high for the processing of small tools, torque is relatively small, focus on the "engraving" function, such as wood (specialized processing of wood called wood carving machine), double color board, acrylic board hardness is not high board, not suitable for strong cutting large pieces.At present, most of the products on the market under the banner of engraving machine are mainly for processing handicrafts, low cost, due to low precision, not suitable for mold development But there are exceptions such as chip engraving machines.Ģ,High speed cutting machine tool is used to complete the medium milling amount, and to reduce the milling grinding amount to the minimum processing equipmentģ,The non-moving part is very rigid and the moving part is very rigid and as light as possible.Īdvantages: can be in small amount of cutting (general 10 flat knife, for 45 steel (300) depth of 0.75 is good) Disadvantages: the correct use can play a high efficiency, low cost, so that the grinding quantity into a minimum.If you don't use it correctly, you'll soon have a mountain of tool waste.ġ,as the name implies.It can be accurately carved, but also milling, engraving machine on the basis of increased spindle, servo motor power, the bed bearing force, while maintaining the high-speed spindle, the more important is the accuracy is very high.Engraving and milling machine also to the high-speed development, generally known as high-speed machine, cutting ability is stronger, the machining accuracy is very high, but also can directly process the hardness of HRC60 above the material, a molding.Ģ,The rigidity of the non-moving part requires that the moving part should be flexible and as light as possible while maintaining a certain rigidity.Īdvantage: can carry on the fine machining, the machining precision is high.The soft metal can be processed at high speed.įaults: heavy cutting is not possible due to poor rigidity.ģ,CNC engraving and milling machine requires high-speed CNC system, spindle speed of 3000-30000RPMĤ,CNC engraving and milling machine is used to finish small milling, small die finishing, suitable for copper, graphite and other processing It is generally considered that the CNC engraving and milling machine is a CNC milling machine using small cutting tools, high power and high speed spindle motor.

0 kommentar(er)

0 kommentar(er)